Generate Code

Once you click the “Generate Program” button a dialog will pop up with various options depending on which make of robot you have. If you do not have a valid license to generate a code an error message will be displayed. Please see the relevant section below for your robot make.

For some robots, in addition to saving the generated code to your computer, you also have the option of transferring directly to your robot if appropriately connected.

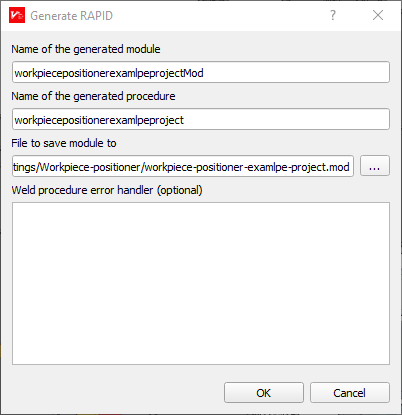

ABB

ABB Generator Dialog

The dialog has the following options:

Name of the Generated Module: The name of the generated ABB module.

Name of the Generated Procedure: The name of the generated ABB main procedure within the module that should be called to run that exported group of welds.

File to save module to: Filename of the generated *.mod file

Weld procedure error handler (optional) Optional handler for errors that occur during weld procedure.

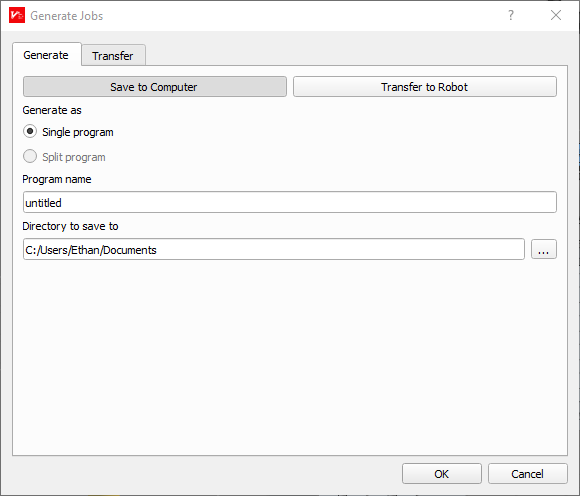

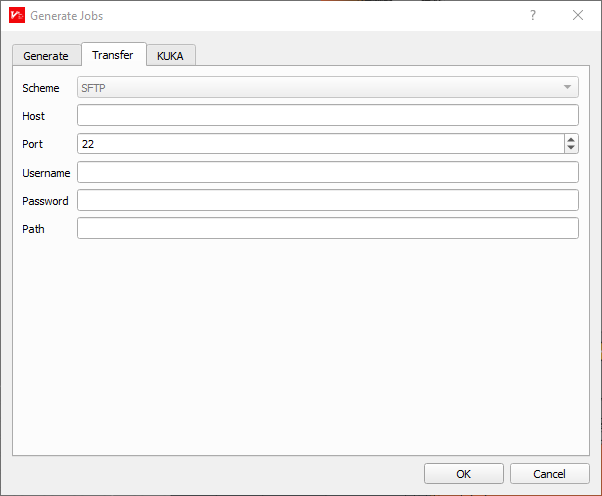

KUKA and Universal Robots (UR)

UR and KUKA Generator Dialog

Both the KUKA and UR code generators have the following options:

Single program or split program to generate the code as one combined or several smaller programs with a main program to call them in order.

Program name specifies the name of the main program. An error will be shown if the name contains invalid characters.

Directory to save to All output files will be written to this location.

The KUKA and UR generator also allows for:

Transferring to the robot to upload the code directly to your robot instead of saving to your computer

Transfer: Allows you to transfer the generated code to a server.

Output ArcTech channels as: KUKA ONLY - Specify the format to output ArcTech Channels (Program ID by default)

UR and KUKA Transfer Dialog

If there is an issue generating code, error messages will be shown in red. Warning and information messages may also be shown, but they will not prevent code generation.

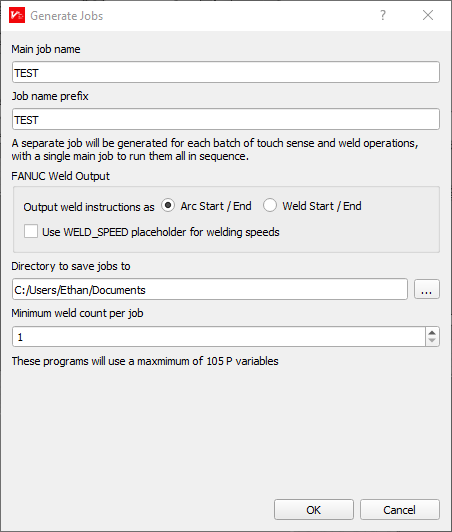

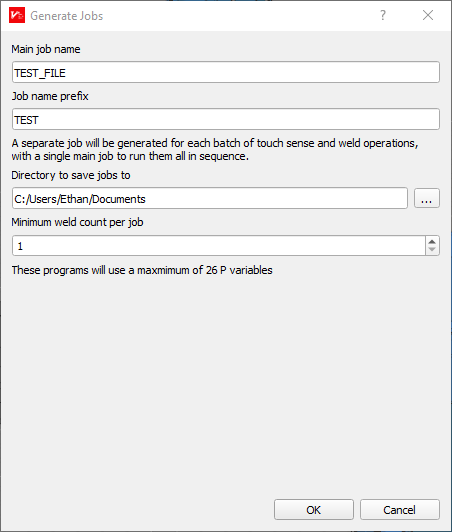

FANUC

FANUC Generator

The following options are available.

Main job name: The name of main job that will call the smaller jobs created.

Job name prefix: The prefix to use for each smaller job.

FANUC Weld Output controls how to weld control code is generated:

You can output weld instructions as

Arc Start[...], Arc End[...]orWeld Start[...], Weld End[...].You can use the

WELD_SPEEDplaceholder instead of the actualy weld speed.

Directory to save jobs to: Directory to save all the generated

.lsfilesMinimum weld count per job: The minimum number of welds to add in each smaller job.

Please note for FANUC robot controllers there is a limited number of variables that can be used to store the path calibration data used by the generated programs. Verbotics Weld will allow users to split a larger program into smaller jobs that will re-use these variables.

Yaskawa Motoman

Yaskawa Motoman Generator

The dialog has the following options:

Main job name: The name of main job that will call the smaller jobs created.

Job name prefix: The prefix to use for each smaller job.

Directory to save jobs to: Directory to save all the generated

.jbifilesMinimum weld count per job: The minimum number of welds to add in each smaller job.

Please note for Yaskawa Motoman robot controllers there is a limited number of variables that can be used to store the path calibration data used by the generated programs. Verbotics Weld will allow users to split a larger program into smaller jobs that will re-use these variables. The generate code dialog will tell you how many P variables will be used by the generated program.