New in 0.10

The following features additions and major changes were made in Weld 0.10.

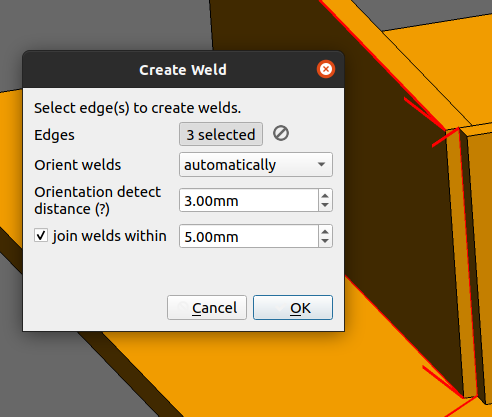

Manual weld creation

In 0.10, a manual create welds tool has been added. The direction and groove angle of the created weld can then be defined either automatically, semi-manually or manually.

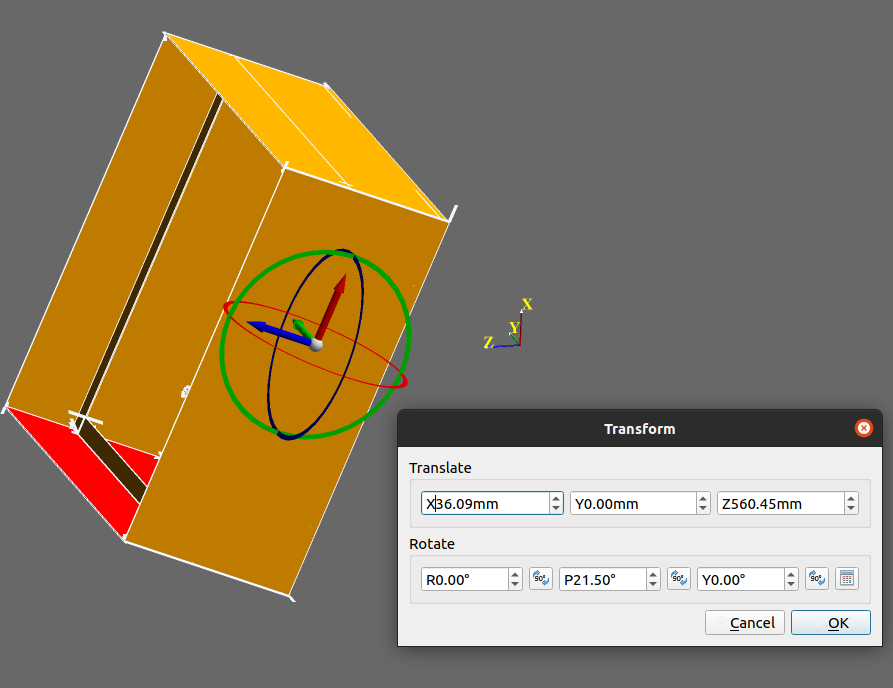

Improved Translate / Rotate

When translating and rotating assemblies in the workspace, a 3D manipulator can now be used to control the transformation alongside the existing transform dialog.

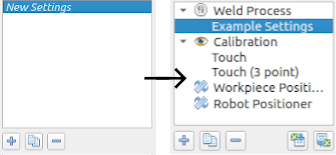

Separated weld settings user interface

Weld settings have been separated into separate sections for Weld Process, Calibration and Positioner Settings. These changes also mean that calibration and workpiece settings can now be set per-weld. A number of new configurable settings are also now available for welds;

Wire rotation can now be constrained.

Settings can now be imported and exported.

When touch sensing or laser sensing, part accuracy can now be configured with independent settings.

A Maximum spacing can now be configured for calibration operations, to improve accuracy over long welds.

Additional options to control touch sense operations, including avoiding touches near welds and avoiding curved surfaces (which can produce inaccuracies.)

Many additional options to configure the behaviour of laser sensing on supported hardware, including avoiding reflections and limiting the laser incidence angle.

Allowing control over the individual axis of the robot positioner with many configurable settings.

Add the ability to apply weld settings to new welds by default.

Hide unused weld settings for Yaskawa and Fanuc robots.

Additions to split/trim

The split/trim welds dialog has had its display reworked to show the actual weld as it will appear after the operation.

In addition, the ability has been added to relocate splits along welds where the splits have already been made.

Relocation of existing corners

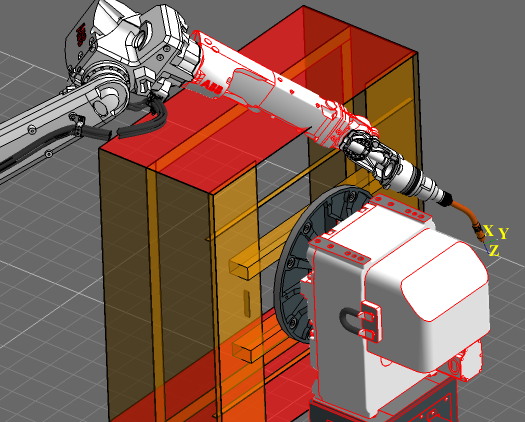

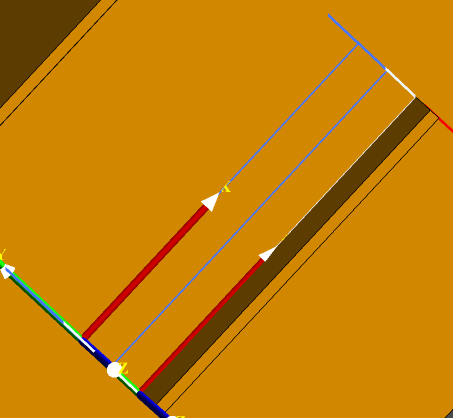

Improved Visualisation

The 3D view now outlines colliding links with red.

The copy welds dialog has been improved to provide better visualisation, showing the copied welds with a blue colour. A coloured trihedron is placed where the copied welds will lie.

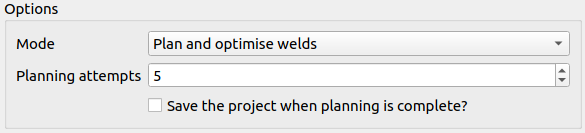

Plan dialog

The plan dialog now provides settings to control whether to optimise the welds when planning. The project can now also be configured to save automatically when planning completes.

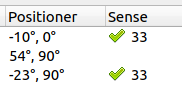

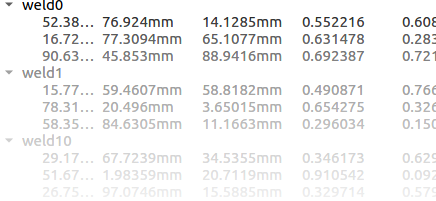

Updated weld widget

The Weld widget has been updated to include the positioner range and number of senses at the start and end of the weld.

CSV Import

The CSV weld importer has had drastic stability improvements. In addition, the tool now imports the weld Groove Angle.

Many other fixes and improvements

Incremental improvements to motion and weld planning, improving both speed and accuracy.

Fix an issue where hidden parts were shown when opening a project.

When sorting by positioner values, normalise revolute joint angles.

Fix crash when copying multiple welds.

Fix issue where hitting OK on transform welds dialog without changing anything would hide welds.

Show a more descriptive error when opening deleted / unreadable files.

When re-ordering welds, insert them in their listed order.

Don’t cut wire before laser sensing (only touch sensing).

Don’t clear existing plans when changing program speeds.

Add world / workpiece reference frame option to TCP position view.