5. Fixtures and Assemblies

Tutorial

This tutorial will walk you through the full extent of the various components you can import into Verbotics Weld. It’ll explore importing supports, fastening devices and multi-part assemblies as well as how to prepare these for proper use in your welding project.

Prerequisites and Resources

Before starting with the tutorial, ensure to have downloaded and installed the ABB FlexArc Example cell which is available from our website.

In addition, make sure to have downloaded the weld table and workpiece assembly example parts.

Video Tutorial

Step by Step Guide

Step 1 - Fixtures and Supports

The first part of this tutorial looks at importing and preparing fixtures/supports. In addition to the regular parts you would import to be welded, tables that would support your workpiece and fixtures that hold parts in place can also be imported.

The initial plate for the ABB Flexarc Sample Cell isn’t able to hold or support our part properly. To fix this, we’ll import a step file of a weld table to be attached to the workpiece positioner. Open the import part function and select the “weld_table.step” file.

Once imported, you’ll find the table will need to be repositioned to sit correctly on the platter. There are 2 methods to doing this:

Method 1: Adjusting the Translate and Rotate Values

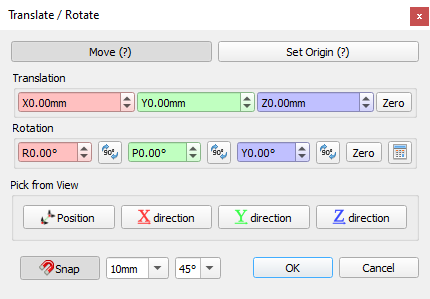

Once the table has loaded in, select the “weld_table” from the workspace widget and open the

transform/rotatefunction from the context menu (right-click on part in workspace to see context menu).Using the values shown in the table below, adjust the “weld_table’s” position, then click

OKto confirm the transform.

Option |

Value |

Translate X |

383.0 mm |

Translate Y |

449.0 mm |

Translate Z |

-360.0 mm |

Rotate R |

90° |

Rotate P |

0° |

Rotate Y |

0° |

Method 2: Using the Set Origin Mode and Pick From View Options

With newer versions of verbotics, a simpler, easier and more accurate method is to use the new Set Origin mode to reposition an assemblies origin to a preferred location, then using the Position option found in Pick from View to select the exact location to snap a part to.

Once the table has loaded in, select the “weld_table” from the workspace widget and open the

transform/rotatefunction from the context menu (right-click on part in workspace to see context menu).Set the mode to

Set Origin, and selectPositionin the Pick from View section.Select the circumference of the tables base from the viewer.

Set the R rotation to

270in order to correctly align the origin with the tables orientation.Set the mode back to

Move, then again selectPositionin the Pick from View section.From the viewer, select the large origin shown for the platter to snap the table into position.

Zerothe rotation of the table then clickOKto set the tables position to the correct location and orientation.

Transform / Rotate Dialogue with Set Origin and Pick From View Options

This new method avoids having to attempt to try and line up the part manually using the manual viewer controls or by changing the translate or rotate values until the part appears correct.

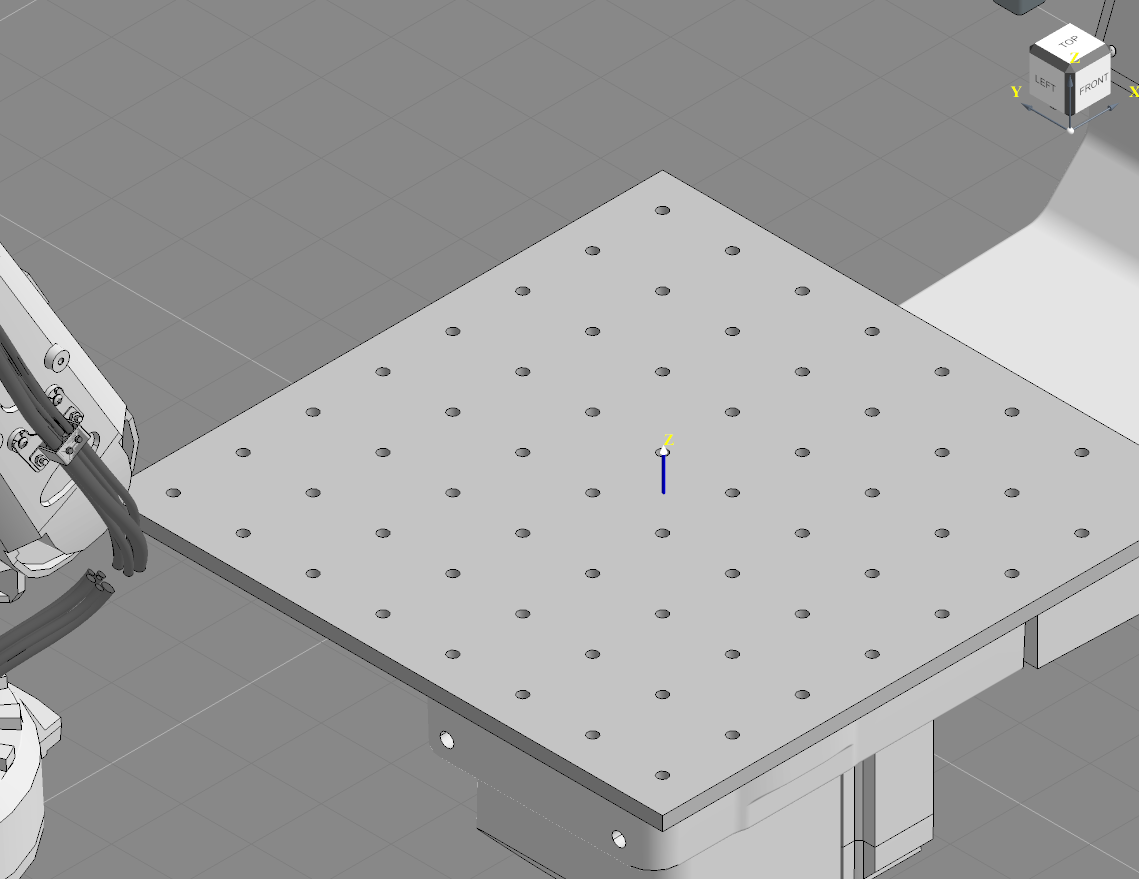

With the table imported, the final step for preparing the table is to set the component to act as a support instead of a weldable part. This can be done in 2 ways:

Right-click on the “weld_table” in the workspace widget and uncheck the

weldableoption.Select the “weld_table” in the workspace widget, then in the details widget below uncheck the box labelled

weldable.

Table Prepared as a Support

Importing the Workpiece and Preparing the Fasteners

With the table in-place, the next step is to import the workpiece:

Open the

import partfunction and select the “workpiece_assembly.step” fileSelect the “workpiece_assembly” from the workspace widget and open the

transform/rotatefunction from the context menu (right-click on part in workspace to see context menu).Using the values shown in the table below, adjust the position of the “weld_table”, then click

OKto confirm the transform.

Option |

Value |

Translate X |

0 |

Translate Y |

0 |

Translate Z |

40.0 mm |

Rotate R |

90° |

Rotate P |

45° |

Rotate Y |

0° |

Note

You can also use the Position pick from view function to snap the assembly to the top of the table, then simply rotate the part until it sits correctly.

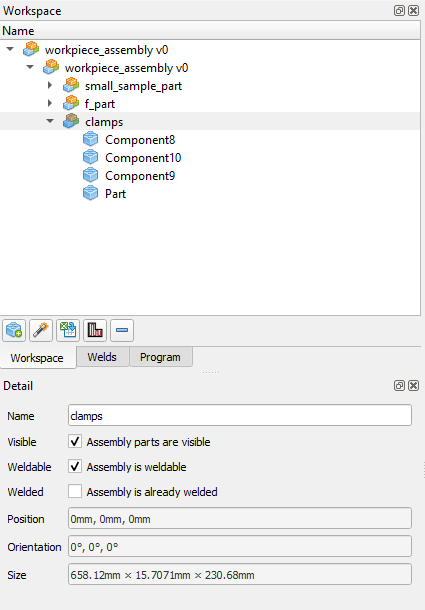

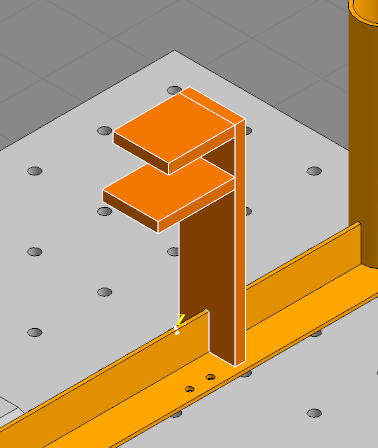

You should now have a workpiece sitting upright on the table. Now we can go ahead and prepare the fasteners. To do so, navigate to the group of parts named “clamps” in the workspace.

Clamps Sub-Assembly

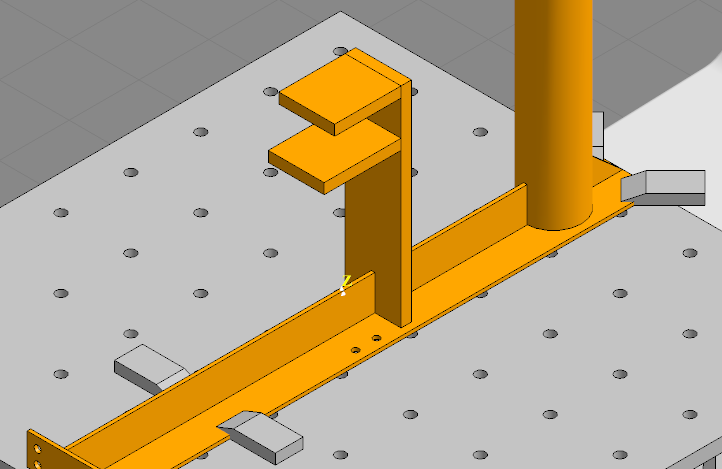

These 4 clamps will be used to hold our workpiece in place, however once again we need these to be considered as supports and to not be weldable. Similar to before, select the “clamps” from the workspace and then uncheck the weldable option.

Non-Weldable Clamps

Note

When parts are checked as weldable, they will appear as yellow whereas parts that aren’t weldable will appear as grey. Sub-assemblies set as “already welded” will appear as orange.

Step 2 - Assemblies and Preparing Sub-Assemblies

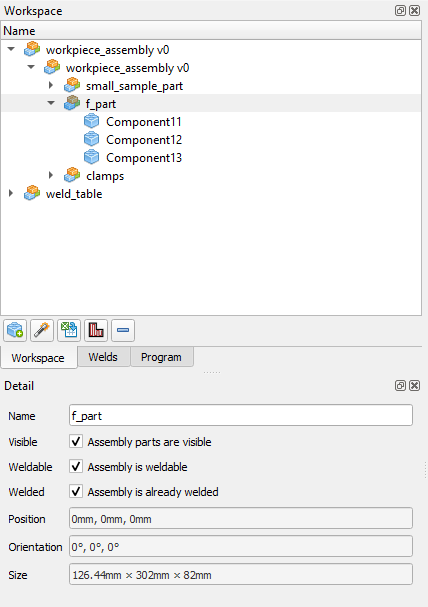

Upon importing the workpiece, you may have noticed the assembly consisted of several sub-groups of parts. These sub-groups are referred to as sub-assemblies, and with verbotics, we can adjust and manipulate sub-assemblies independently from the rest of the assembly without needing to detach the two.

Starting at the top-most layer, you can see our “weld_table” and our “workpiece_assembly”. If we were to select the “table_assembly”, you’d see every part that makes up that table. Any adjustments we make at the assembly level will affect every part and sub-assembly it consists of.

Moving on, if we click the arrow next to the workpiece assembly, you’ll see how now it’s expanded to show its 3 sub-assemblies. At this level, we can select sub-assemblies and apply specific adjustments to each one. We already did this before with the clamps sub-assembly when we set them as not-weldable, however we also can move, rotate and alter the visibility of sub-assemblies.

Let’s try this out with the sub-assembly labelled “f_part”.

Select “f_part” from the workspace, then right-click and open

transform/rotate.Instead of using the transform window to adjust the position, click and drag the part in the view to move it relative to the workpiece assembly.

Move the “f_part” slightly along the workpiece then click

OK.

In addition to the weldable option we explored previously, assemblies and sub-assemblies can also be set as already welded. Select the “f-part” in the workspace and locate this option in the details widget.

Altering the f_part Sub-Assembly

For this project, the “f_part” has already had its 3 parts welded previously, so check the welded checkbox.

f_part Sub-Assembly Prepared as Already Welded

Finally, let’s click the arrow left of the small assembly part in the workspace. This will expand to now show all the parts making up the sub-assembly. Here, we can adjust each part individually, however many of the options regarding parts has been covered in our previous tutorials.