Robot Calibration

Offline programming requires an accurate representation of the workcell to be created in order to minimise the modification required to a generated program. Verbotics Weld typically expects and error of around 5mm between the theoretical kinematics of the system and the real-world system.

This document outlines some measurements that can be completed with the robot system to determine the main calibration parameters required for your system. Using this information, Verbotics can provide an assessment of the suitability for you welding system to be programmed using Verbotics Weld. Verbotics can also provide calibration services where required. These can be quoted upon request.

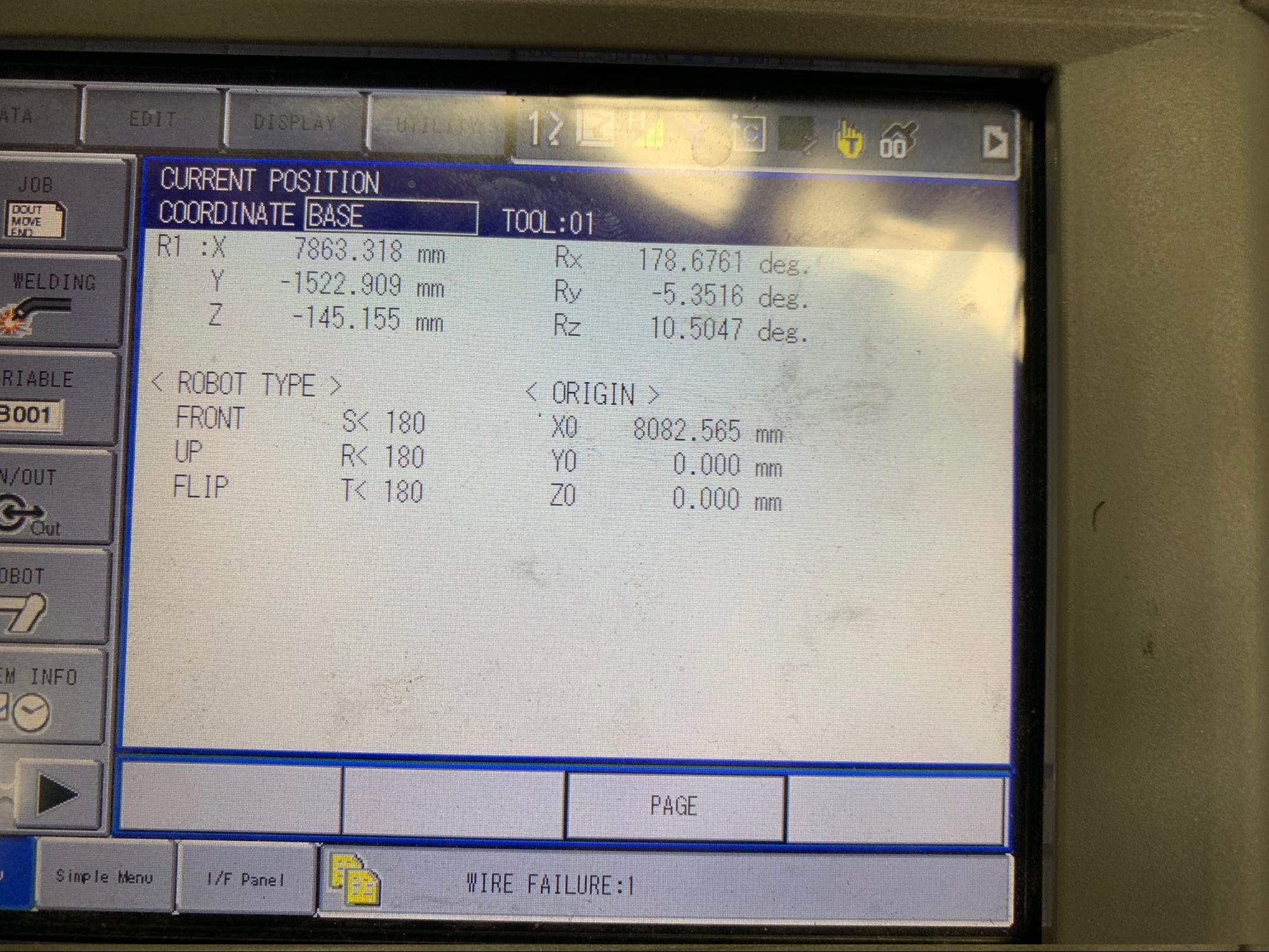

Pictures of the teach pendant can be used for the purpose of recording this information:

TCP Calibration

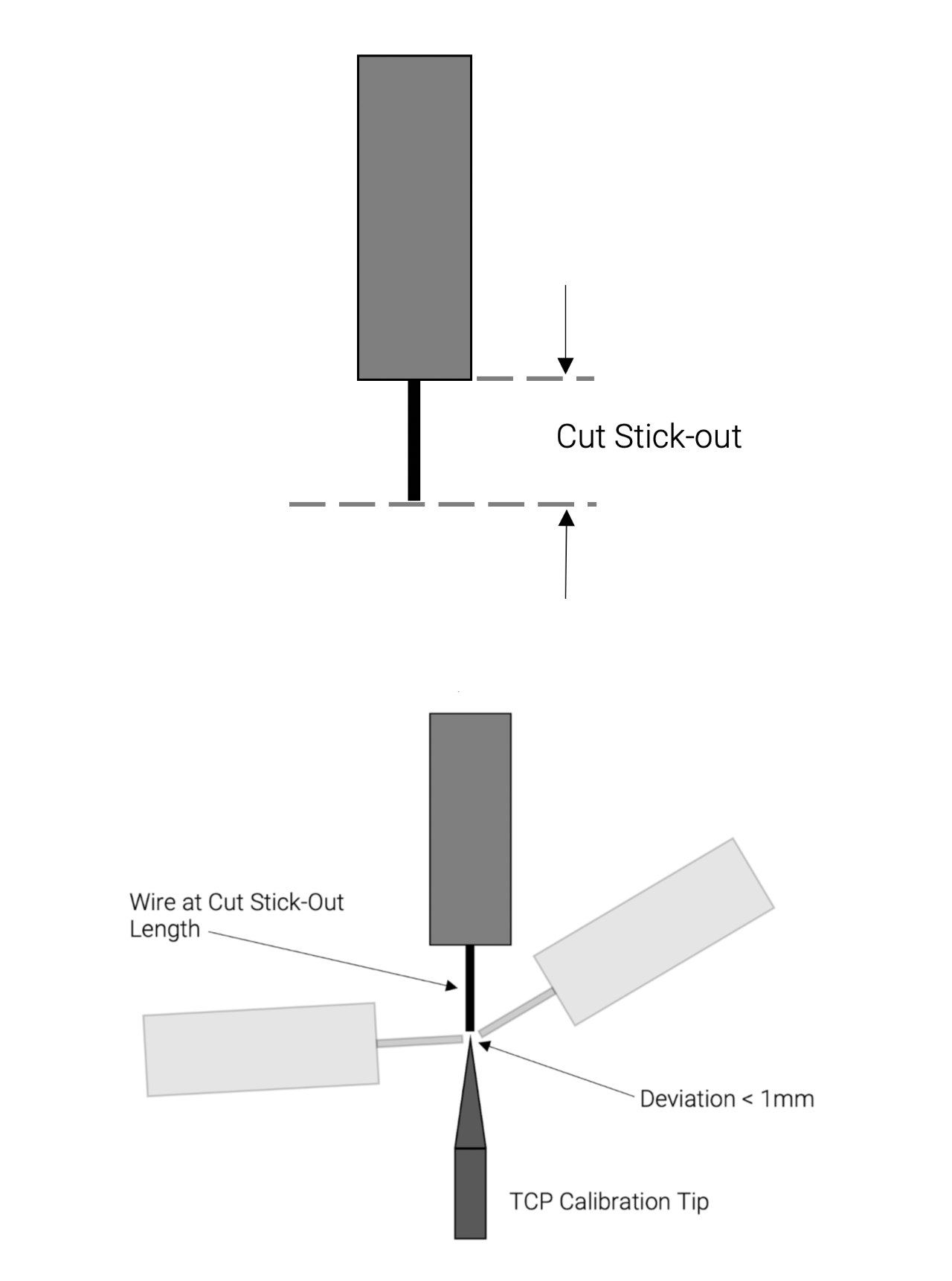

The TCP should be calibrated such that the cut-wire length is known (stick-out), and such that the position of the wire end (at the cut-wire length) deviates less than 1mm in all reachable orientations. The cut-wire length should ideally be between 17mm for MIG welding applications.

This calibrated TCP should be used for all subsequent calibration activities. Take care to ensure that the wire position does not change when taking recording measurements to maximise accuracy. Also ensure that the correct tool is selected when taking measurements.

TCP Calibration

The rotational component (Rx, Ry, Rz) of the TCP is not required at this point. Verbotics will supply these values to align with the TCP rotation in the Verbotics Weld workcell based on the torch model used.

Parameter |

Recorded Value (TCP) |

|---|---|

Cut Stickout (mm) |

|

TCP X (mm) |

|

TCP Y (mm) |

|

TCP Z (mm) |

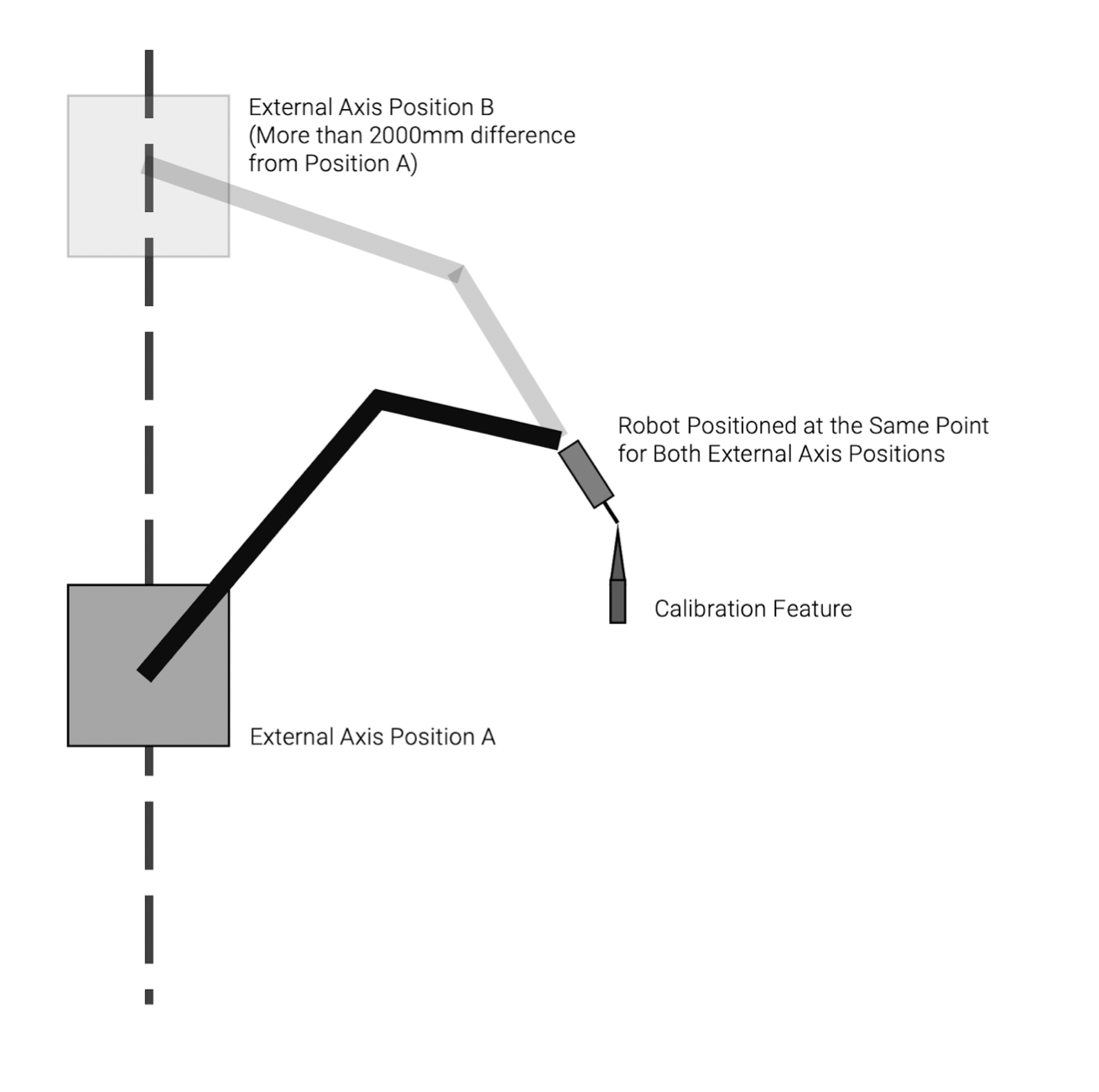

Robot Rotation on External Axis

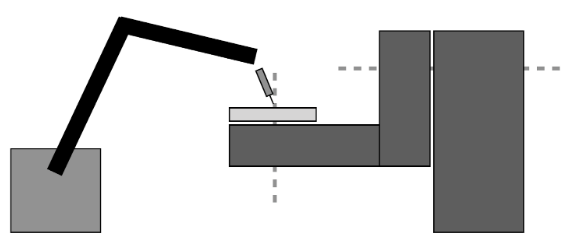

In some cases there may be a rotation between the robot and any external axes. This can be determined by measuring a point in space from multiple base positions and recording the robot coordinates (in cartesian space) at each point. The orientation of the tool should be unchanged for this measurement. We will use the supplied values to determine this rotation and apply to the supplied Verbotics workcell model.

This process should be repeated for each independent linear axis if there are more than one (for example a gantry robot).

External rail calibration

Parameter |

Recorded Value (Base Frame Coordinates) |

|---|---|

External Axis Position A (mm) |

|

Robot X (mm) |

|

Robot Y (mm) |

|

Robot Z (mm) |

|

External Axis Position B (mm) |

|

Robot X (mm) |

|

Robot Y (mm) |

|

Robot Z (mm) |

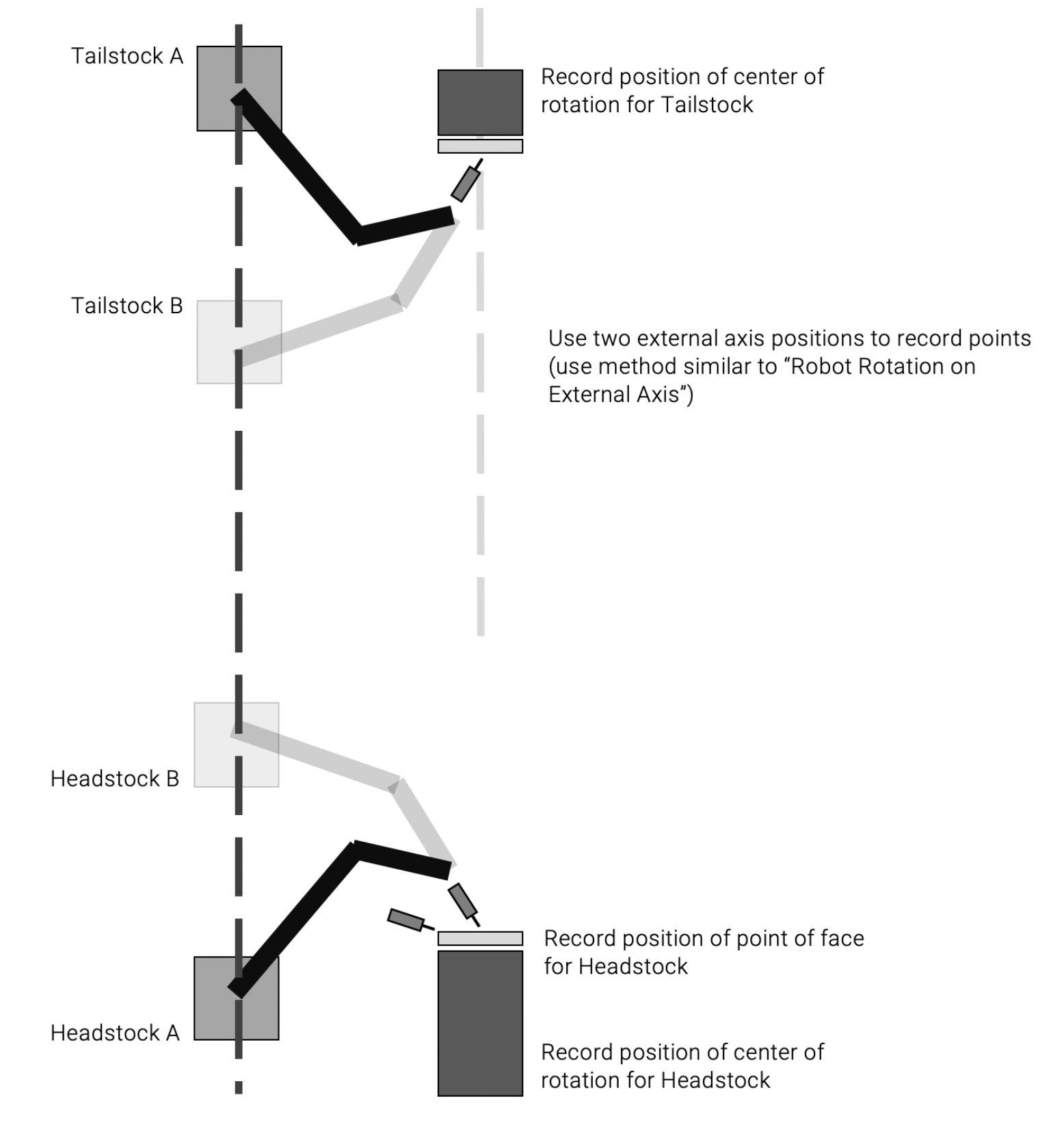

Headstock / Tailstock Calibration

The axis of rotation for the headstock / tailstock should be known in the robot base coordinate system. This can be determined using the robot TCP placed at the center of the headstock / tailstock axis of rotation. The planar face of the headstock is also required and should be a point on the face.

Headstock and tailstock calibration

Parameter |

Recorded Value (Base Frame Coordinates) |

|---|---|

Headstock Position A - Rail (mm) |

|

Robot X Center (mm) |

|

Robot Y Center (mm) |

|

Robot Z Center (mm) |

|

Robot X Face (mm) |

|

Robot Y Face (mm) |

|

Robot Z Face (mm) |

|

Headstock Position B - Rail (mm) |

|

Robot X Center (mm) |

|

Robot Y Center (mm) |

|

Robot Z Face (mm) |

|

Tailstock Position A - Rail (mm) |

|

Robot X Center (mm) |

|

Robot Y Center (mm) |

|

Robot Z Center (mm) |

|

Tailstock Position B - Rail (mm) |

|

Robot X Center (mm) |

|

Robot Y Center (mm) |

|

Robot Z Face (mm) |

2 Axis Positioner Calibration

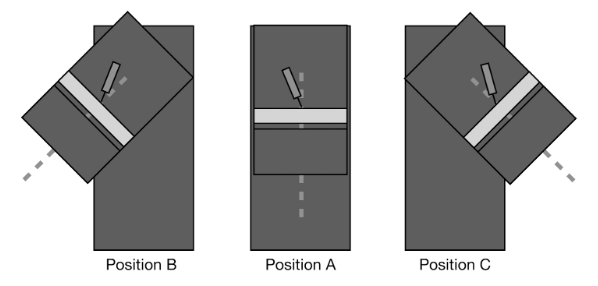

Each rotation axis of a 2 axis positioner should be known in the robot base coordinate system.

This can be determined using the robot TCP placed at the centre of the second axis of rotation (typically the mounting plate) for three different joint positions for the first axis. One of the positions should be with a first axis joint position of 0 degrees.

If the robot is mounted onto a rail this position should be left unchanged for all measurements.

Record the position of the centre of the second axis against the mounting face.

Repeat for three different positions for the first axis.

Parameter |

Recorded Value (Base Frame Coordinates) |

|---|---|

Rail Position (mm) |

|

Axis 1 Position A - 0 degrees |

0° |

Robot X Axis 2 Center (mm) |

|

Robot Y Axis 2 Center (mm) |

|

Robot Z Axis 2 Center (mm) |

|

Axis 1 Position B (deg) |

|

Robot X Axis 2 Center (mm) |

|

Robot Y Axis 2 Center (mm) |

|

Robot Z Axis 2 Center (mm) |

|

Axis 1 Position C (deg) |

|

Robot X Axis 2 Center (mm) |

|

Robot Y Axis 2 Center (mm) |

|

Robot Z Axis 2 Center (mm) |